Infoline

Factory flow and production performance management

Digitisation of integrated plant control.

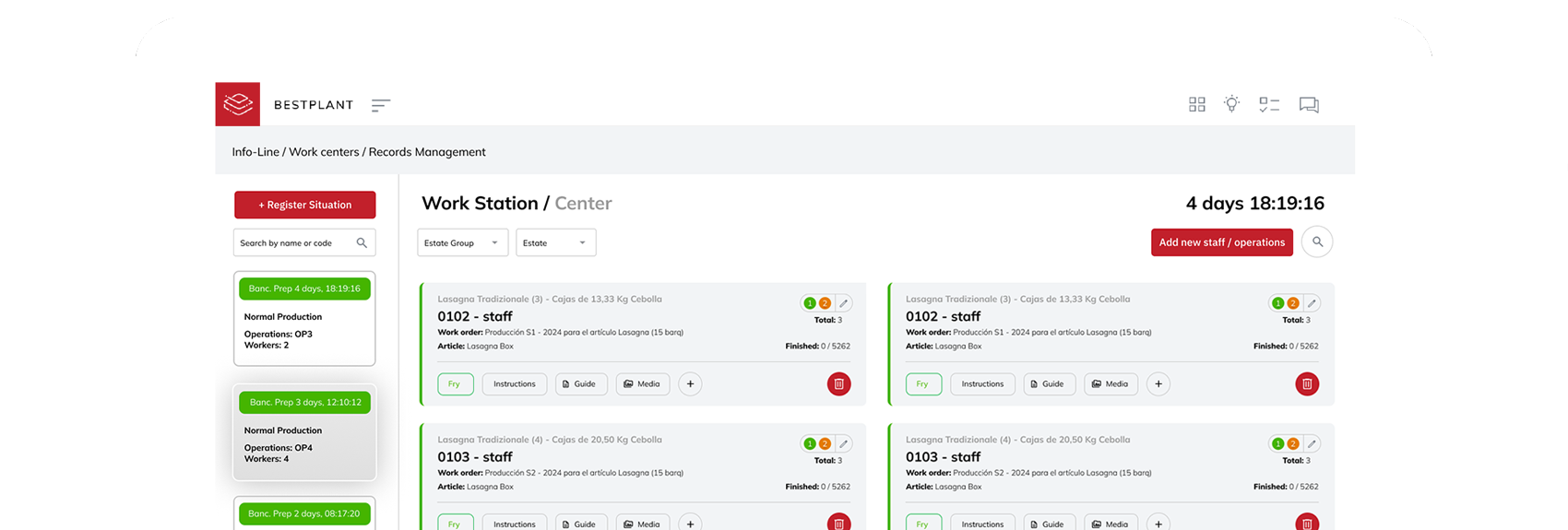

Real-time display of the progress status of orders, work centres, and personnel.

Operator interaction screen with the system, with information on work orders, data entry, self-monitoring forms, and visual aids.

Organisation and management of access to machine set-up forms, process quality, or other forms necessary for the execution of work orders.

Work-in-process (WIP) monitoring

All plant personnel can see the status of progress in real time in the fulfilment of work orders by product, work centre or other variables configured in the system. This visual information facilitates the management of priorities, possible delays or incidents that appear in the course of production.

The information presented is updated automatically and in real time according to the recorded progress process.

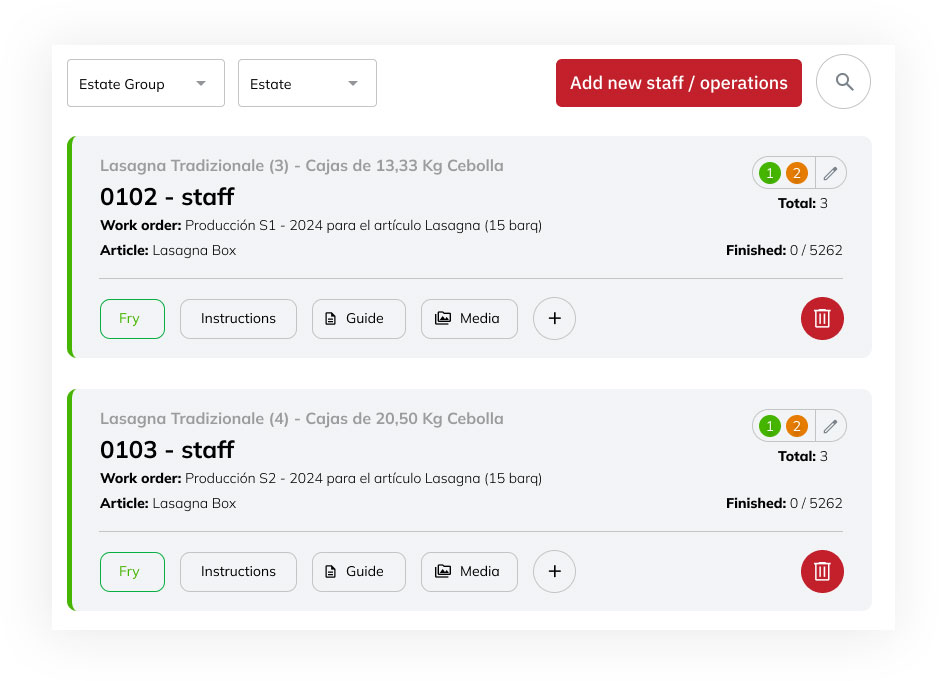

Records Management and Visual Aids

Facilitates the manual entry of data and qualitative information on the state of the production process by the operator. It allows the identification of the articles and operations assigned to each work centre. The operator has visual aids and access to plans, work instructions, videos, in order to facilitate his work and improve his work learning.

The system automatically picks up machine signals in order to provide a clearer reading of the status of the work centre. The combination of both machine and manual signals gives a more accurate reading of the status of the production process and performance levels.

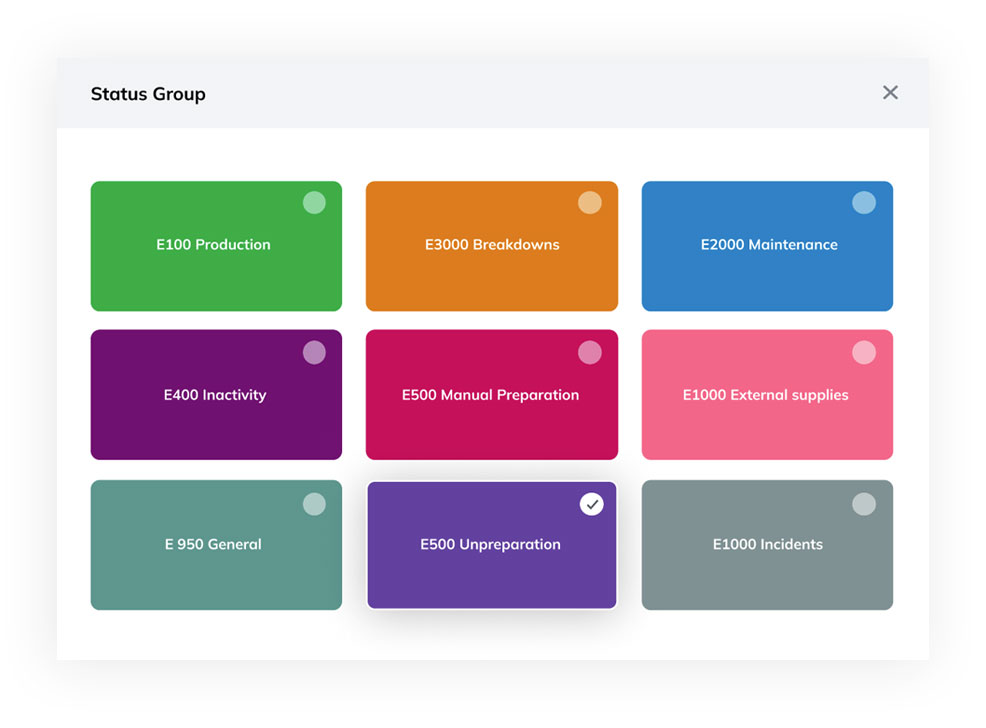

Digitisation of Autocontrols

Each work centre has automated access to the required control forms at each stage of the process. The control guidelines can be for machine preparation, in-process quality controls, picking preparation, records of materials consumed, final product validation…

Likewise, the generation of forms can contain multiple types of records, with fixed or variable formats depending on the controlled product. Likewise, the information can be conditional according to responses, include numerical fields, dates, units of measurement, visual information about the product and many other variables that can be configured independently for each client.

Other functions

Production Planning

Organisation and optimisation of the sequencing of work activities according to criteria of time, availability of raw materials and components, machine occupation.

Machine data reading

Real-time reading and processing of data received from equipment or other information bases, management of alerts and processing of the information received.

Traceability eBook

Automated generation of results reports in the form of an electronic book for consultation of the information processed and maintenance of the traceability of the processes.

AND MUCH MORE..

Cutting-edge software for Industry 4.0

What can we do for you?

Please send us your information and be part of Bestplant today.

¿Do you want more information about our solutions?

Request a demo to guide you through the process of making the most out of your data.

Do you want to work with us?

Working with us means developing a professional career in an inspiring and creative work environment.